The home was constructed in 2003. It is in Marion County. In a phone conversation with the county offices I was told that while a building permit is required, there are no building inspectors and no adopted code to build under. Code is a standard to which builders around the world must comply. There are a few different building codes in the US, but the intent is the same: to bring a standard to building construction that will yield a safe building that performs well. Various material manufacturers write the specifications for their materials to either comply with code minimums or even higher standards. I will refer to a couple of code citations in this report, even though there is

not an adopted code in this county. I use this to point out minimums to which any builder should comply when hired to construct a dwelling that is expected to give a reasonable performance and not have issues with moisture intrusion and excessive damage and rot in its first five years of existence.

Roof:

The roof is shingled with an asphalt composite shingle. There is no underlayment applied to the roof sheathing under the shingles. Ice dam membrane is not applied to the eaves of this home. IRC2003 R905.2.7 Underlayment application. For roof slopes of four units vertical in twelve units horizontal (33 percent slope) or greater, underlayment shall be one layer applied in the following manner. Underlayment shall be applied shingle fashion from the eave and lapped 2 inches, fastened sufficiently to hold in place. End laps shall be offset by 6 feet. IRC2003 R905.2.7.1 Ice protection. In areas where the average daily temperature in January is 25°F or less or when table R301.2(1) criteria so designates, an ice barrier that consists of at least two layers of underlayment cemented together or a self-adhering polymer modified bitumen sheet, shall be used in lieu of normal underlayment and extend from the eave’s edge to a point at least 24 inches inside the exterior wall line of the building.

Siding:

The siding on the home is a fiber cement siding I have identified as James Hardie Fiber Cement Board. James Hardie has provided very good documentation as to their requirements for the installation of their products. I have referred to the installation documentation for the period of time in which the home was constructed. The installation of the siding falls short of the requirements put forth by James Hardie in the following areas:

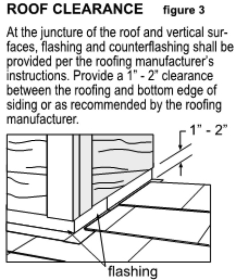

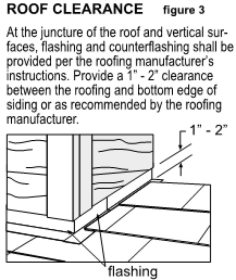

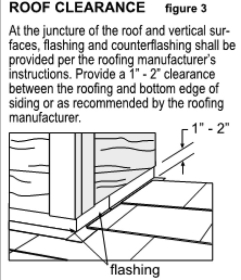

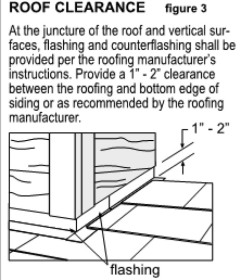

Clearance from the roof line: James Hardie required a one to two inch clearance from the roof line according to the installation specifications in 2003. All of the siding on this home is installed tight to the shingles and caulked. This leads to moisture being trapped behind the siding and the material absorbing this moisture. This moisture expands when frozen and over time fractures and spalls the siding. The siding has a fifty year warranty but will not apply to pieces improperly installed.

James Hardie specifies in its installation instructions “A weather resistant barrier is required.” This note is also in the installation documents: “Some building codes exempt the use of weatherresistive barriers over ‘water repellent panel sheathing’ or exterior panels classified as ‘weatherresistive barriers.’ James Hardie recommends the use of ‘building paper type’ weather-restive barriers with all siding products. James Hardie will assume no responsibility for water infiltration within the wall.”

The butt joints are not properly detailed to resist moisture penetration; many of them have been left alone and butted without any additional detailing. The lack of a WRB in places has left the sheathing at these butts exposed to the weather without protection. There are some areas on this home that are experiencing significant material degradation behind the siding and trim due to the lack of a WRB (weather resistant barrier).

Windows:

The windows on the home are Pella brand windows with a 3.03 date code in the ones I reviewed. Some of the windows are showing rot and degradation at the bottom style on the sash. I recommend consulting with Pella service center to see what your options are. I removed the trim boards from one of the windows to see the details at the nail fin. The window is wrapped with a SAF (self adhering flashing).

Foundation:

The foundation is an ICF: (insulated concrete form). The top foam on the exterior of the ICF does not appear to have been flashed or properly detailed to ensure full protection against the elements. There are areas where mesh material has been left exposed and not covered with the parging finish. The sealant in areas is very sloppy in application and not fully adhering to its substrate.

Entry:

The entry roof is sloped away from the house. It appears to be slopped ¼” in four feet less than the entry slab. A slight fall is desired at an entry to keep moisture draining. ¼” in four feet is desirable for this. If the roof was level the slab would have this fall leading me to the conclusion the footings are sinking. The entry slab has been poured on top of a wood joist system. I consider this to be an unconventional building practice. Concrete weighs from 90# to 140# per cubic foot. The point load on a footing would be heavier than a wood decked structure. In my opinion this should be investigated to ensure the footings are not moving.

The following pages are captioned pictures that describe what I observed and what the installation documents advise. I refer to code in a couple of instances in this report. Code is a minimal standard in a lot of areas and the manufacturers of the various products we use in the assembling of a home either refer to code or go above codes requirements. The lack of a building code in this county does not negate the requirements of the manufacturer.

There are some details of protection lacking in the assembly of this home that are having detrimental effects and need to be addressed without delay to protect the integrity of this structure.